Predstavitev izdelka

Naše stroj za lasersko rezanje z vlakni collocates with the advanced laser generator which emits laser beam with high energy density. The laser beam is focused on the surface of workpiece as an ultrafine focus facula and causes the irradiated area instantly melted and vaporized. Automatically controls the laser cutter to achieve the cutting mission. The laser equipment is constituted with the advanced laser technology, CNC technology and mechanical technology. It's applicable to processing metal sheets such as stainless steel, carbon steel, copper, aluminum and metal pipes. It has been widely used in plate processing, machinery manufacturing, and precision processing, etc.

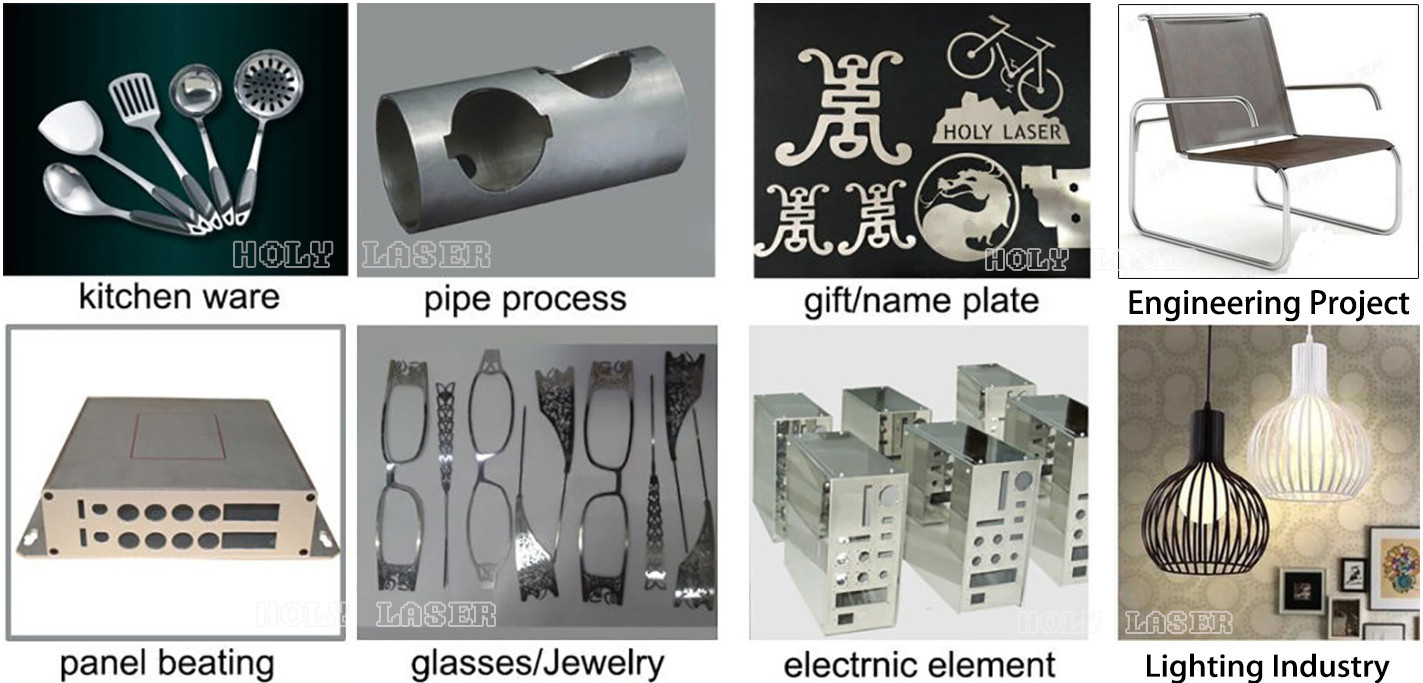

Aplikativne industrije

Naše stroj za lasersko rezanje kovin applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Uporabljeni materiali

Naše stroj za lasersko rezanje mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Prednosti Fiber laserski stroj za rezanje

1) Odlična kakovost snopa: Manjši premer ostrenja in visoka delovna učinkovitost, visoka kakovost.

2) Visoka hitrost rezanja: Hitrost rezanja je več kot 45m / min

3) Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours

4) Visoka učinkovitost za fotoelektrično pretvorbo: primerjajte s CO2 laserskim rezalnim strojem, stroj za lasersko rezanje z vlakni ima trikratno učinkovitost fotoelektrične pretvorbe

5) Low cost & Low maintenance: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine. Fiber line transmission no need reflect lens, save maintenance cost

6) Easy operations: fiber line transmission, no adjustment of optical path

7) Super prilagodljivi optični učinki: Kompaktna zasnova, enostavna in prilagodljiva proizvodna zahteva

8) Dvojni pogon: drugačen je od običajnega pogonskega stroja, večja je moč dvojnega pogona, hitrejša je hitrost in visoka procesija

Tehnični parameter

| Model No | ACCURL 500W-3015 |

| Laserska moč | 500W |

| Laserska valovna dolžina | 1080 mm |

| laši sredi | YVO4 |

| min širina vrstice | <0,15 mm |

| pogon | dvojni pogon |

| največja hitrost vožnje | 60m / min |

| max delovna površina | 3000 * 1500mm |

Z os | 120 mm |

| debelina rezanja iz ogljikovega jekla | 6 mm |

| Napetost | 380 V / 50 HZ |

| Hladilni način | Vodno hlajenje |

| Natančnost lokacije | ≤ ± 0,05 mm |

| Podporna oblika | PLT, DXF, BMP, AI |

| Delovni stol max. obremenitev | 1000KGS |

| Način prenosa | Krogelni vijačni prenos |

| Sistem, ki ga poganja tabela | Japonski uvoženi servo motor in vozni sistem Panasonic |

| Metoda ostrenja | Sledi in samodejno prilagodi fokus |

| Metoda nadzora | Nadzor gibanja brez povezave |

| Programska oprema za nadzor | Cypcut Laser Cutting Software |